Description

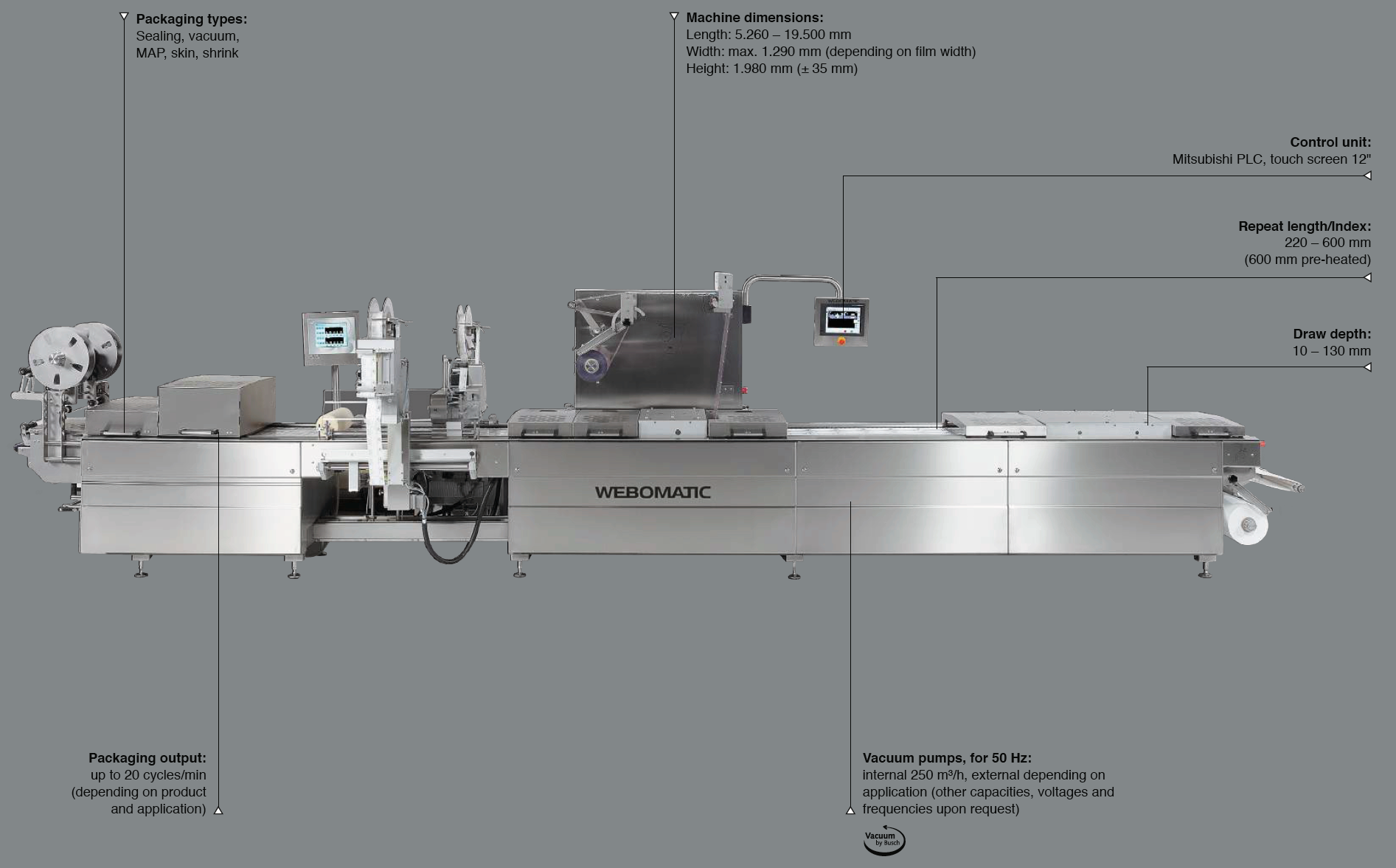

Thermoforming Machine ML-C 5600

The thermoforming machine ML-C 5600 meets medium and high production requirements. With its modular design it can be optimized flexible to any customer’s request and to whole packaging lines.

Standard equipment:

WEBOMATIC CleanDesign® WEBOMATIC sealing technology WEBOMATIC SDTDescription

ML-C 5600 The thermoforming machine ML-C 5600 meets the highest demands for industrial sized production while it is designed for large production environments and is suited for high-speed operation. With its film width, repeat length/index and optimized lifting movement, the machine is ideal for automated operation in a packaging line with integrated slicers, pick-and-place robots, multi-head weighers etc.

The innovative lifting system including compact hygienic cylinders and a double knee lever ensure a high closing pressure of the format die for precise movements and formidable packaging designs. To reduce compressed air consumption, a combination with individual stroke adjustment and lifting are simple but efficient. Also, vacuum valves are placed directly at the die. This means even shorter ways to create vacuum and that adds up to a quicker production. Depending on specification, the ML-C can process rigid films up to 1.200 μm with a width of up to 562 mm in repeat lengths up to 600 mm.