Description

Application

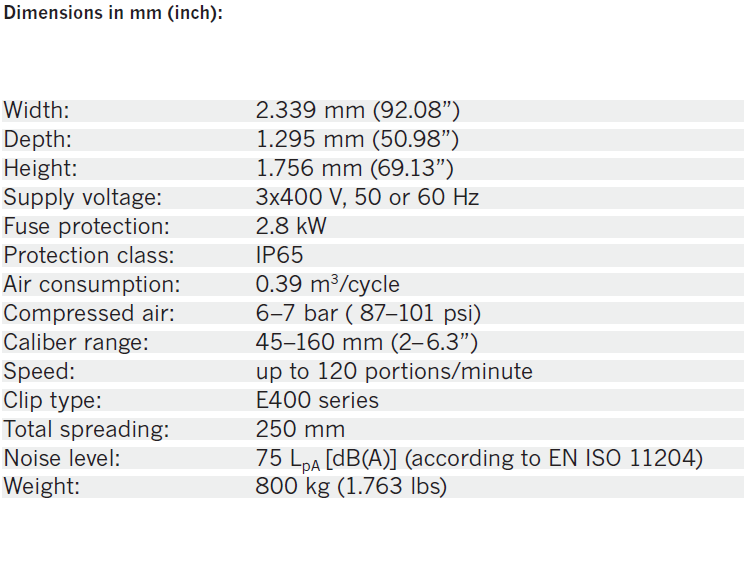

The TIPPER TIE SV4800 is the ideal clipping system for slicer ware and shaped products. All known plastic, fibrous and collagen casings can be processed fast and safely.

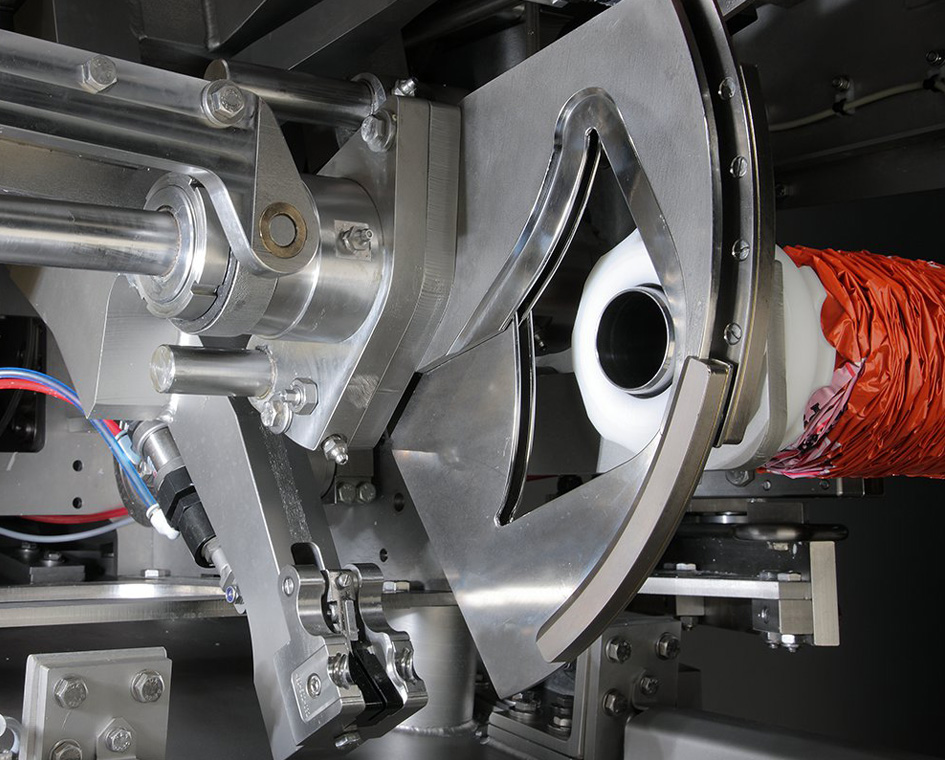

It closes all kinds of sausage, such as scalded, raw and cooked sausage as well as shaped products with diameters 45–160 mm. The SV4800 is the result of many years of experience and systematic product development. The new spreading voider system allows processing of ham products with all standard artificial casings up to caliber 160 mm. For air-free slack filling the SV4800 can optionally be equipped with an overspreading device for total spreading up to 250 mm.

Technology

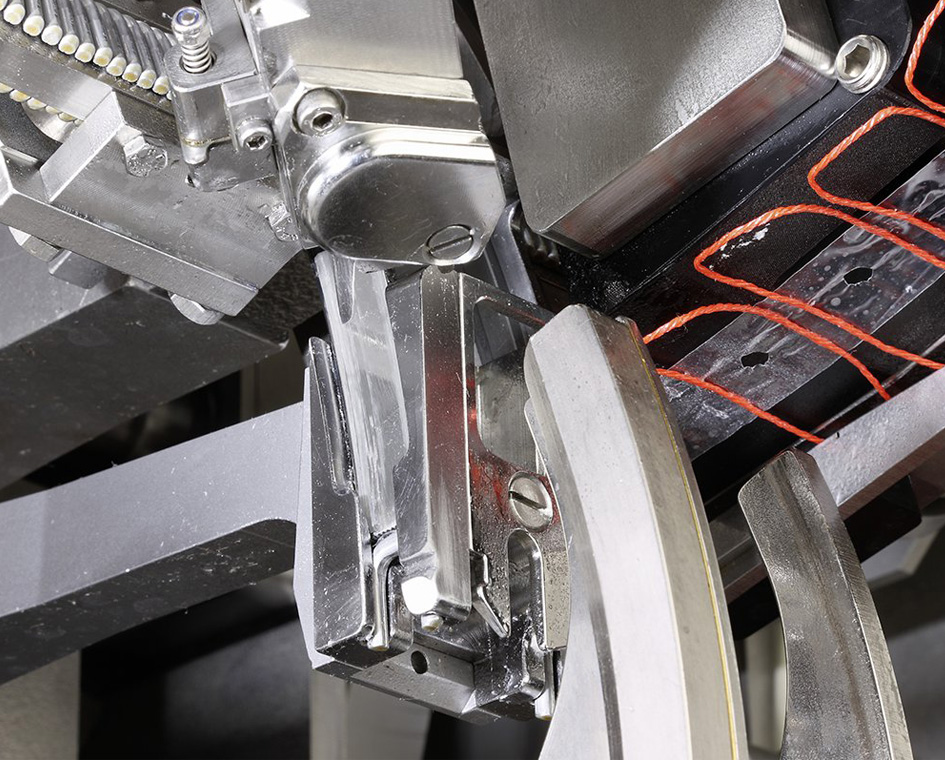

The shuttle clipping technology allows production speeds up to 120 portions/minute. The SV4800 is both the fastest and the most quiet spreading voider for U clips in the world.

The clip pressure monitoring system prevents machine damage due to operating errors. If the set threshold value of the closure force is reached, the safety system is triggered and stops the machine.

A quick-release swivel mechanism for the casing brake allows fast casing change without moving the clipping head. Maintenance and downtimes can be minimized considerably, which increases machine service life. The optional revolving dual horn turret allows casing changes with virtually no downtime for maximum productivity.

The swivel-mounted discharge conveyor ensures a consistent caliber of the products due to programmable and infinitely variable conveyor belt speeds. The discharge conveyor height can be easily adapted to the product.

Customers with limited space or very long products may choose the SV4800 side discharge configuration. This saves one product length in footprint.

The optional labelling system TagPrint TD60 is the perfect basis for a consequent traceability of the products. It ensures comprehensive control of the complete process chain from the manufacturer to the end user. The labels are printed and clipped during production. By adding information such as date, weight, logos, barcodes, etc. products may be individually labelled.

Control

The SV4800 convinces due to its production speed of up to 120 cycles/minute, its quiet operation and powerful and maintenance-free PLC controlled servo drive. The speed can be set in 6 steps and adapted individually to every product.

Efficient operation made easy: Machine control via touch screen, graphic user interface with practical pictographs and easy menu structure. Parameter settings of product programs can be easily managed and stored. An integrated monitoring system controls all safety functions and indicates upcoming maintenance work as well as incorrect machine status.

Hygienic

The SV4800 is very maintenance and service friendly. Smooth, stainless steel surfaces, excellent accessibility of all areas and inclined horizontal surfaces allow fast and hygienic cleaning. A cleaning drawer in the lower safety cover, a swivel-mounted conveyor belt as well as the patented «Easy Clean» stuffing horn ball are design elements which leave nothing to be desired in terms of hygiene. The drive is located in a closed, air-conditioned switch cabinet for protection against water.

Complete clipping system

The total package from TIPPER TIE: clipping machines, clips and loops for many hours of safe, uninterrupted operation. Our clips are designed to the exacting specifications including dimensions, shape and alloy to ensure reliable operation.

The loops are available in many different colors and leave no residue on the carrying tape during the clipping process. Your products can be individually coded. Colored clips or loops, embossed clips or clipped labels are excellent means for product identification.