Description

Area of Application

The SVF1800 is the ideal solution for processors requiring a cost-effective automatic double clipper that produces clean sausage tails. Dependable, shift-long production is easily achieved thanks to robust construction and superior clipping technology – hallmarks of the TIPPER TIE brand.

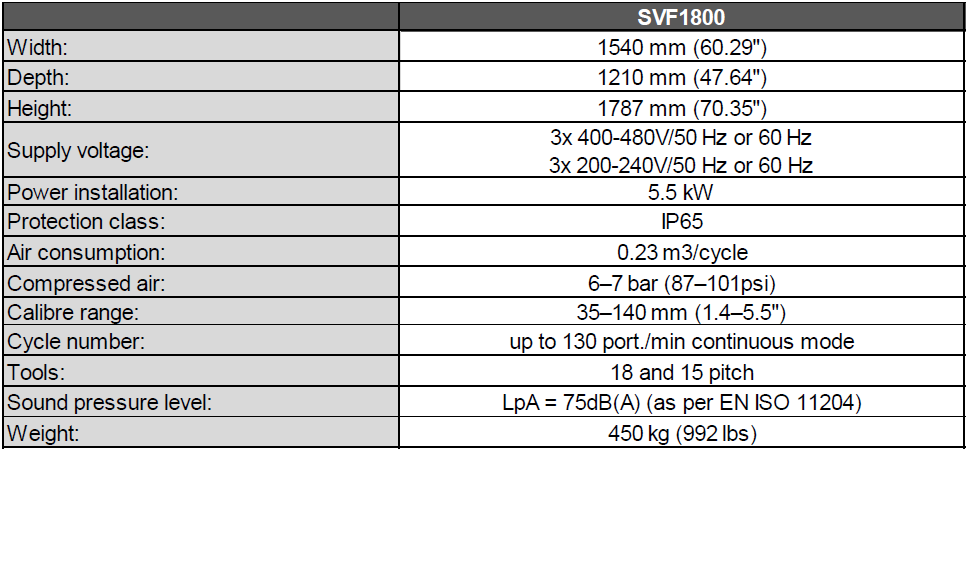

The system is also a perfect choice for companies needing to produce larger caliber products. The SVF1800 closes all plastic, fibrous, and collagen casings in a broad range of calibers from 35mm to 140mm. Easy change to a different clip pitch – from 15mm to 18mm – expands versatility of the caliber range and enables individual use.

The robust SVF1800 can be connected to all conventional filling machines to produce individual, string, and ring sausages in precisely sealed portions without sausage residue in the casing ends. It may also be used for packaging semi-finished confectionery products, cheese, soups, and non-food products.

Technology

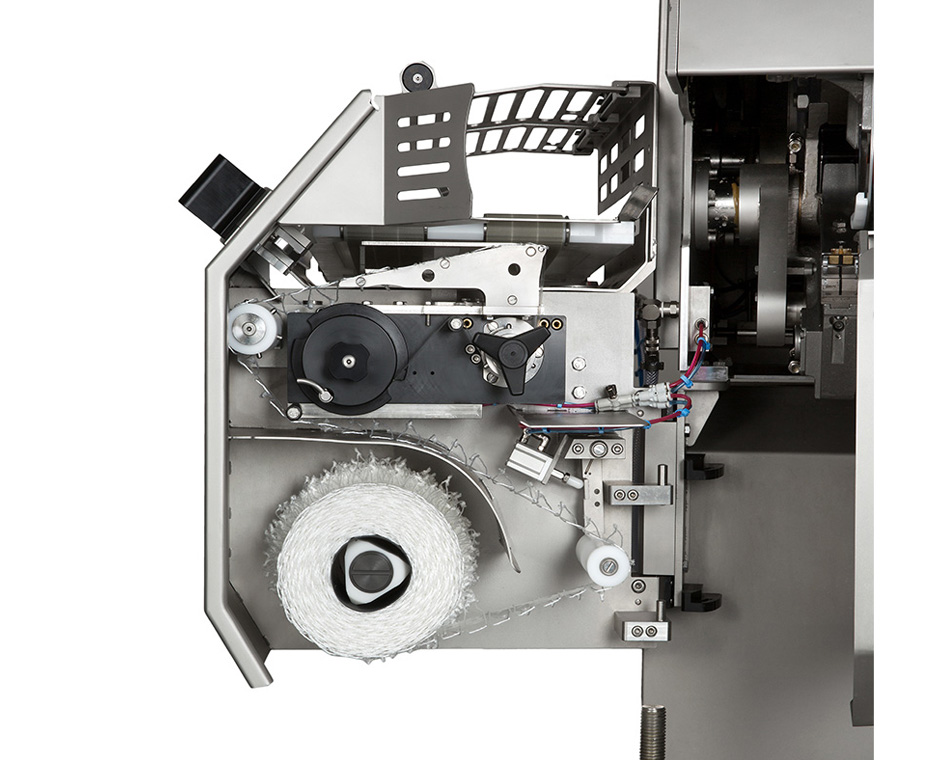

Secure clip closure is accomplished via a heavy-duty, camdriven fixed head. To prevent machine damage from improper operation, the system accurately senses motor function overload from clip closure force above the set threshold value. The safety system is then triggered and stops the machine. This is achieved without the use of external sensors or cables, which can sometimes fail. SVF1800 is constructed of durable stainless steel, including all drive levers. All elements of the cam drive give the SVF1800 long service life with minimum wear.

Touch screen technology enables manual control of the clip cam for maintenance and quick selection of parameters for knife and tool changes as well as for cleaning position. Lubrication is easy using a simple four-position process.

Control

The user-friendly operating system set-up and configuration make essential features accessible through clear graphics and plain text that can be displayed in any of several languages. Both the maintenance-free servo drive and PLC control are operated through the touch screen.

Hygienic Design

The SVF1800 incorporates the latest design elements to ensure the utmost in complete service and easy maintenance. Cleaning is fast and thorough due to smooth stainless surfaces without bolt heads or corners where dirt can accumulate, horizontal surfaces with 3° inclines and IP65 rated components. Hermetically sealed covers protect valves, drive and controls from water and dirt.

Equipment Versions

- String loop feeder BSZ 105-2

- Single clip setting

- String dispenser for ring-shaped products

- Mechanical and visual length portioning

- Three discharge designs

- Clip coding

- Pneumatic casing brake for sensitive casings

- Casing end detection

- Optional wheel kit

Advantages

- Proven clipping reliability from high performing TT1815 series

- Spreading voider provides clean sausage tails

- Ergonomic, compact design for high operating convenience

- Touch screen control with recipe storage for quick product changeover

- Manual clip cam adjustment via touch screen

- Knife, tool change and cleaning position selectable via touch screen

- Easy conversion to a different pitch with Click-Clip feed

- Electric clip closure force monitoring without external sensors

- Full access for service and maintenance for maximum uptime

- Hygienic cleaning due to smooth, angled surfaces and IP65 rated components

- Four speeds plus continuous run for maximum productivity