Description

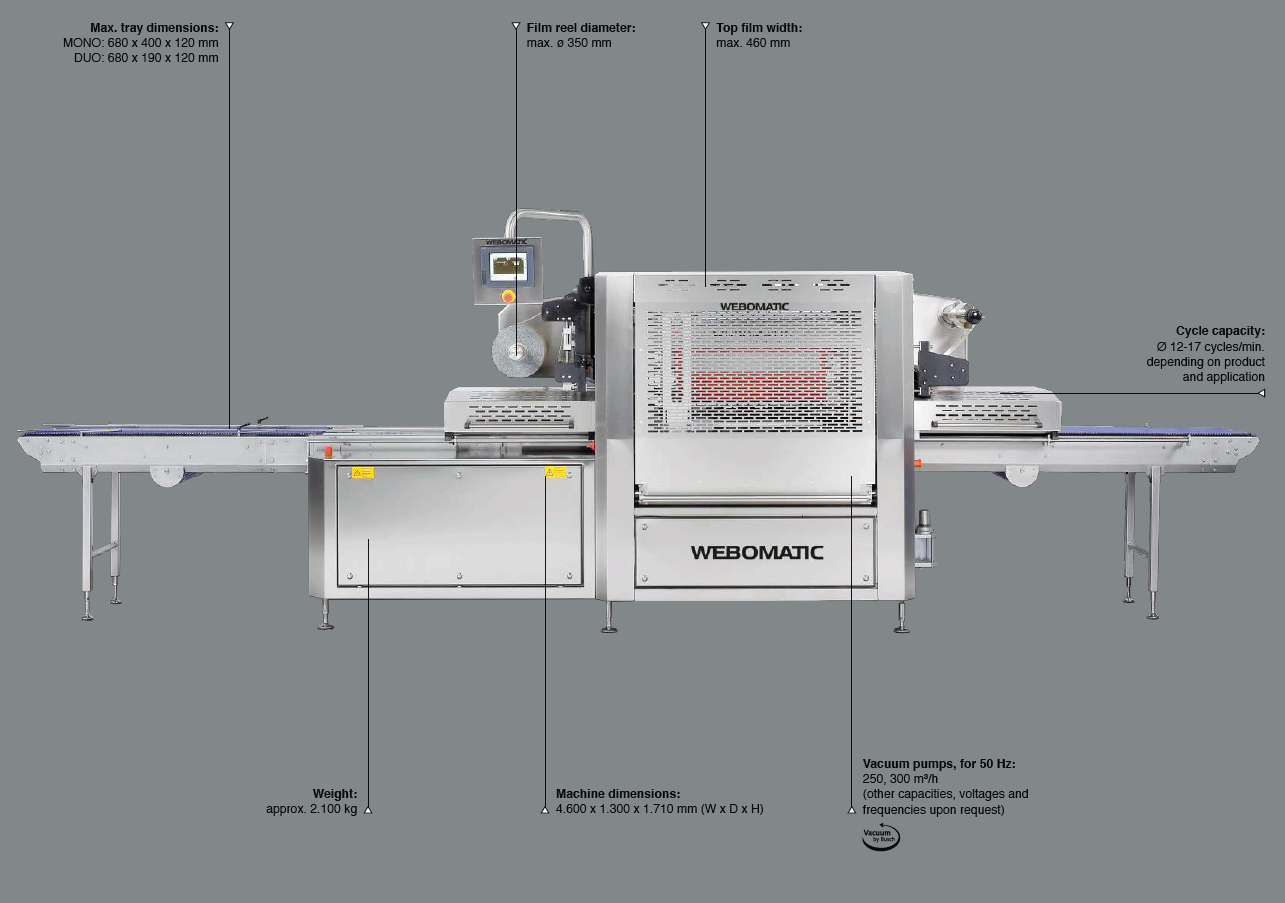

Automatic Tray Sealer TL 750

Fast tool change required? Or would you prefer to create either skin or MAP packaging with a single tool? Even in the event of a malfunction or failure of a sealing unit, still end the production shift on the same machine without having to switch to another line?

Standards:

WEBOMATIC CleanDesign® Fiber Optics In-House-Programming servo-driven gripper arms WEBOMATIC SDTDescription

The TL 750 marks the entry into high-speed industrial tray sealing due to the perfect combination of innovation, design and performance. Additionally, a well-thought-out selection of features supports efficient production on an industrial level.

Standards: WEBOMATIC CleanDesign®, PLC control unit, WEBOMATIC SDT, Fiber Optics, servo-driven gripper arms