Description

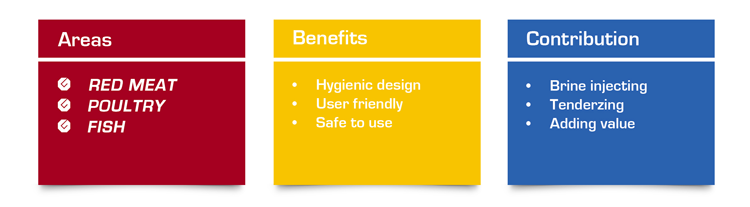

The GAROS Brine Injector and Tenderisers are developed to meet the extensive requirements of the modern meat, poultry and fish industry.

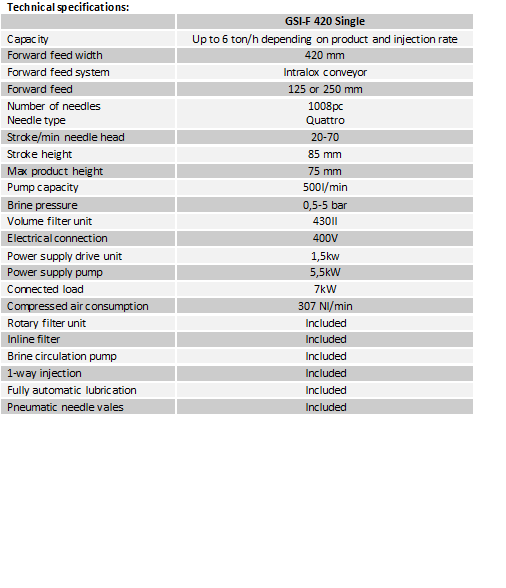

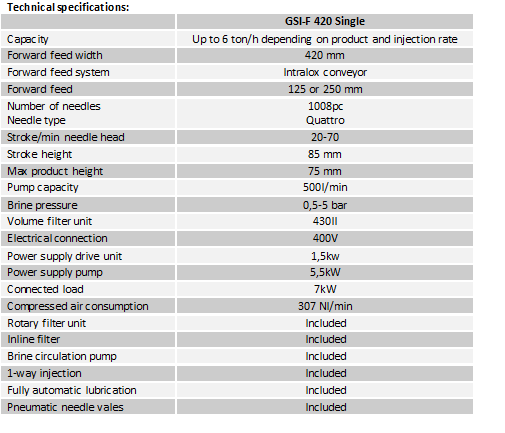

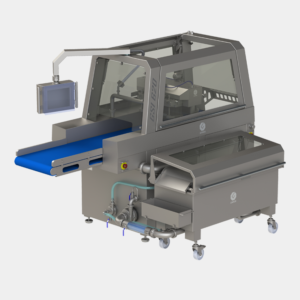

The GAROS range of Brine Injector and Tenderisers have been refined and developed to meet new requirements for uniformity, injection percentages and hygiene within the modern meat, poultry and fish industry. Our fourth generation of machines, GSI are at the forefront of technology. The Premium range comprises three models, GSI 420, 620 and 820, all of which can be supplied as single or double machines. The 620 and 820 are also available as triple machines.

Some of the characteristics and advantages:

- Uniform injection, low SD value thanks to unique flow and ventilation system.

- Flow system adapted to even the most viscous types of brine and marinade.

- Horizontally (HDI) and vertically (VDI) differentiated injection.

- Stainless steel, high-capacity centrifugal pump.

- Separate circulation pump for viscous brine keeps the solution in constant circulation to prevent sedimentation at the bottom.

- Valves that are pneumatically controlled and completely maintenance free.

- Automatic draining after injection.

- Automatic washing program.

- Fully visual control and movable arm during injection process.

- Rotating filter with 4-stage filtration.

- Automatic self-cleaning inline filter.

- Fully automatic lubrication with alarm system.

- PLC control with 15-inch color touchscreen panel or manual control.

- Designed high hygienic standard and minimal service and maintenance.

- All standard components are well known brands, such as SEW, Mitsubishi, Telemecanique, Siemens and Bosch Rexroth.

Brochure Injector

Brochure InjectorVideo

Video